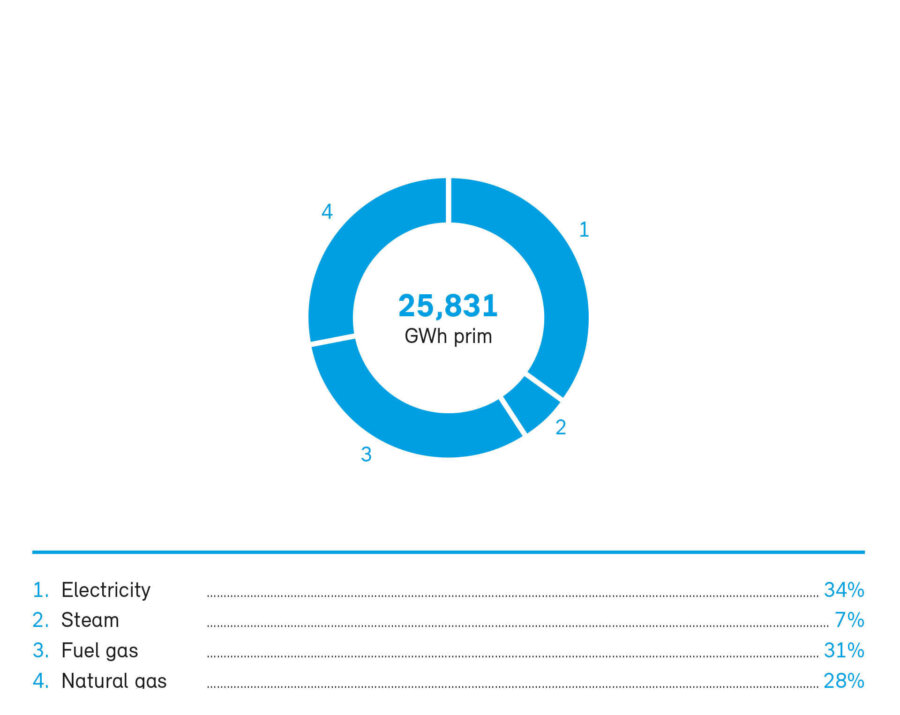

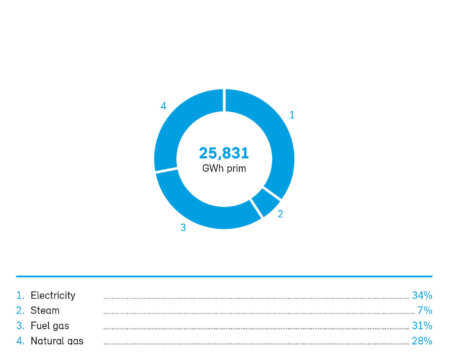

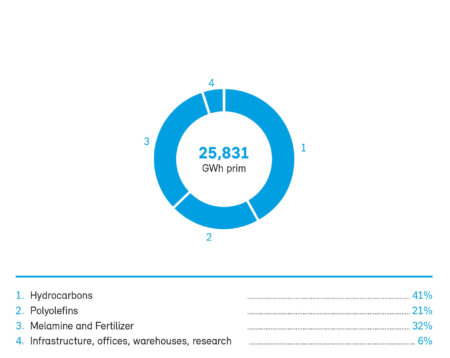

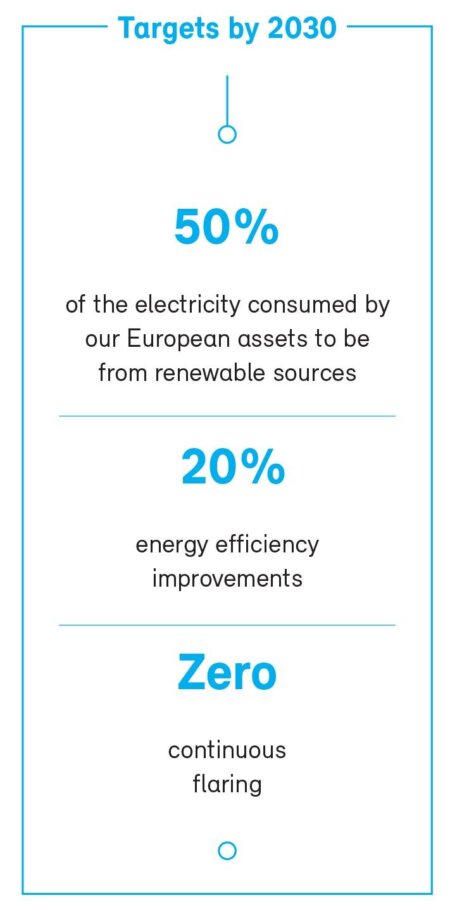

Borealis therefore aims to continuously reduce its energy footprint through greater energy efficiency and by developing innovative solutions that save energy along the value chain. These solutions range from lightweight plastics to chemicals used for renewable energy solutions and accurate fertilizer dosing in farming. Borealis also looks to increase its use of renewable energy.

Flaring is a necessary safety measure used in refineries and petrochemical operations, in which excess gases which cannot be recovered or recycled are safely burned. However, the noise and emissions caused by flaring affect surrounding communities and flaring also incurs high costs for the Group. Flaring is incident driven and Borealis strives to reduce the need for it by continuously improving its plants’ operational performance and reducing the number of plant interruptions and upsets. Flaring only occurs in hydrocarbon and polyolefin plants and not at the Group’s production sites that produce fertilizers or melamine.

Issues related to energy and climate change present both risks and opportunities for the Group. The risks include increased costs for energy and for CO2 emission rights, declining social acceptance for businesses emitting CO2 and possible reputational damage as a result.