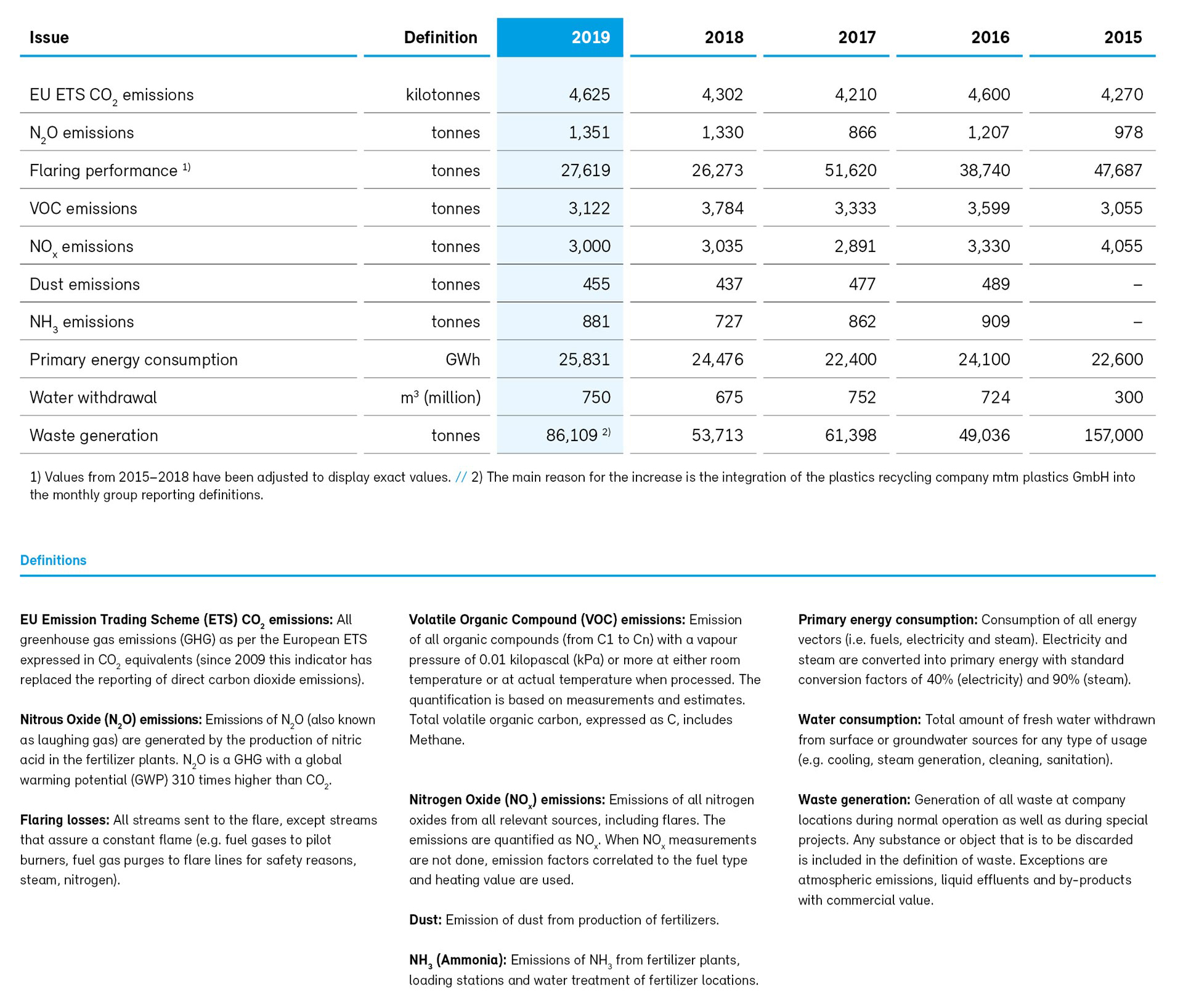

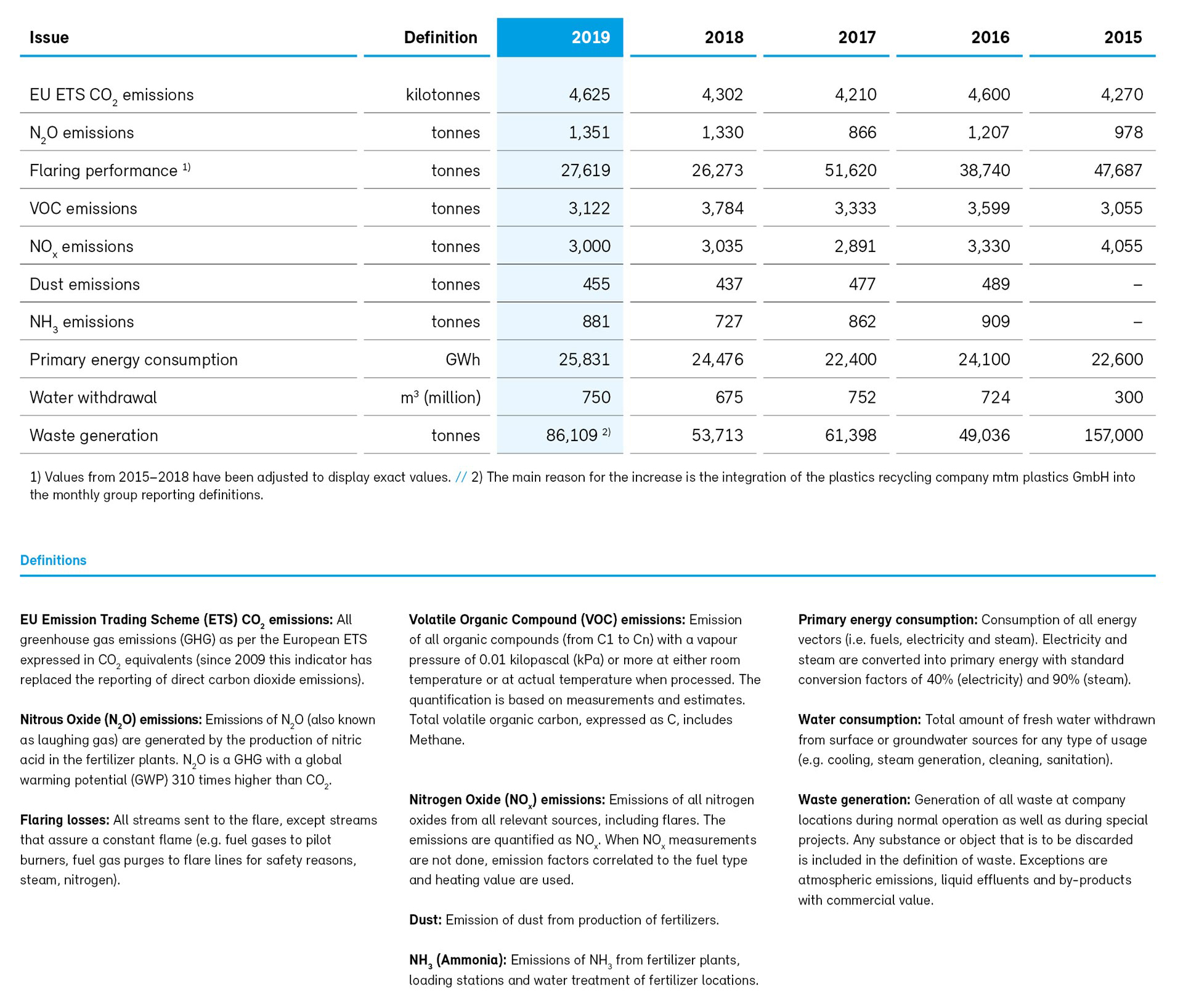

Borealis’ approach to environmental management encompasses managing its emissions to air, its use of water and discharge of wastewater, its production and use of secondary resources in the form of waste, and its overall environmental compliance.

For Borealis, the most relevant environmental impacts from emissions are the contribution to climate change at a global level and the generation of ground-level ozone and eutrophication at a local level.

Borealis’ emissions to air result from its production processes and from combustion for energy generation. In addition to carbon dioxide and nitrous oxide, these emissions comprise:

Borealis requires water for its operations. Industrial water has less strict purity standards than drinking water and is used for production purposes in processes such as cooling, steam generation and product handling. Lower quantities of water are needed for drinking, cleaning, sanitary and firefighting purposes. The Group looks to minimise its water use by recycling water in its production process. It also looks to improve the quality of the water it discharges and to comply with its legal obligations, through filtration, neutralisation and biological wastewater treatment.

The most common types of waste produced in Borealis’ operations include excavated soil, wastewater treatment sludge, solvents, mixed industrial waste and inert construction material. Borealis’ aim is to minimise the production of waste where possible, to treat waste as a resource and to better handle products at end of life.

Borealis is committed to complying with its environmental obligations, recognising that if it failed to meet them, there could be a severe impact on the Group and other parties. The loss of plastic particles could lead to marine litter and emissions of NOx, dust and VOC could affect the air quality of the Group’s neighbours. If such failures occurred, they could result in fines, loss of business, reputational damage, loss of permits and enforcement action by the relevant authorities, all of which could affect the Group’s financial performance.

In 2019, Borealis’ goals were to

During 2019, Borealis:

Borealis is committed to implementing the guidelines of the Responsible Care Global Charter, the chemical industry’s voluntary commitment for continuous improvements in health, safety and environmental (HSE) performance, as well as the Product Stewardship standard of Fertilizer Europe.

At least every three years, the Group performs a detailed and systematic environmental risk and opportunity assessment for every plant in all locations. The assessments are also performed if there have been major changes, near misses, incidents or accidents, or if potential improvements have been identified. The risk assessments are based on an evaluation of the legal framework and possible upcoming changes, any deviations from permit limits and selected stakeholder input.

Based on these assessments, Borealis defines and documents HSE objectives and targets for each location. Clear responsibilities and timelines are agreed and reviewed at the Group HSE level twice a year. The consolidated outcomes, including HSE performance, are reported to the Responsible Care Committee.

In 2019, the Group carried out a materiality assessment. This confirmed that reducing CO2 emissions and energy consumption are the main drivers of Borealis’ performance improvement and have the biggest impact on the environment. It also confirmed that the Circular Economy is a key driver, including a strong focus on packaging waste management.

Nevertheless, emissions to air of NOx, NH3, dust and VOC, as well as water, waste and effluents, also play a significant role in high-quality HSE management. As a consequence, they are included in the Group’s HSE management process and are monitored as part of the environmental objective of each location. All Borealis production locations are part of an ISO 14001 compliant environmental management system.

Borealis uses an integrated environmental data management system and reporting software. This ensures control of data flows from varied sources, in multiple formats and on different schedules, as well the traceability and transparency required for reporting.