Solutions for Polymers

Unlock boundless performance

Explore our advanced portfolio of materials for compounding and polymer modification. These versatile solutions range from soft and flexible to highly rigid and reinforced, as well as ultra-lightweight foamable, all engineered to enhance performance across a wide range of applications.

Applications

Explore our portfolio of soft polyolefin solutions, highly customizable to meet specific requirements for flexibility, temperature performance and toughness.

Backed by proprietary technologies, our comprehensive selection of polypropylene and polyethylene resins enable increased design freedom, optimized processing and enhanced performance.

Our innovative solutions for structured products offer improved performance over conventional materials in terms of weight reduction, design freedom, processability and cost-effectiveness, backed by reliable, local support.

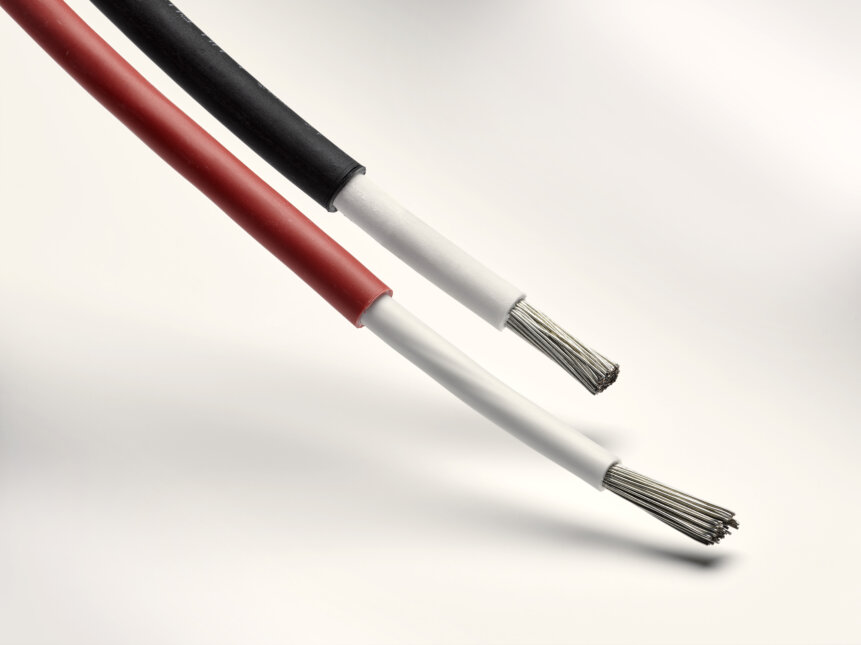

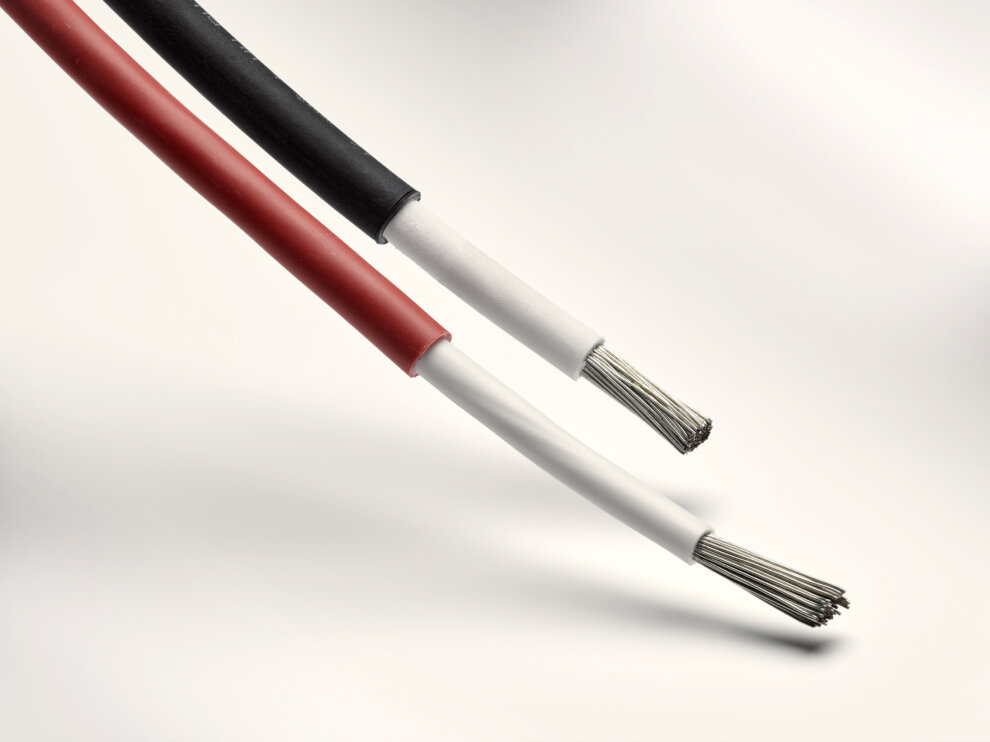

Polymer Modifiers

Explore our portfolio of soft polyolefin solutions, highly customizable to meet specific requirements for flexibility, temperature performance and toughness.

Masterbatch and Compound Carrier Resins

Backed by proprietary technologies, our comprehensive selection of polypropylene and polyethylene resins enable increased design freedom, optimized processing and enhanced performance.

Structured Products

Our innovative solutions for structured products offer improved performance over conventional materials in terms of weight reduction, design freedom, processability and cost-effectiveness, backed by reliable, local support.