Mobility

Moving ahead together

We lead the way in circular technologies and materials, working together with our value chain partners to pioneer a more sustainable future for mobility. Our innovative solutions are lighter, more cost-efficient and globally accessible – accelerating progress across the industry.

Applications

Drawing on decades of experience, we create advanced, sustainable polypropylene (PP) and thermoplastic polyolefin (TPO) solutions for a wide range of specialized interior applications, including dashboards, door panels, center consoles, trims, and structural components.

We leverage our specialized knowledge to create cutting-edge polypropylene (PP) solutions that excel in both durability and aesthetics. Our materials are tailored for a diverse array of exterior applications, from bumpers, to body panels, trims, and more, all the while upholding our commitment to sustainability.

Our innovative polypropylene (PP) solutions are tailored for a broad range of e-powertrain and under-the-hood applications. Whether it's battery applications, front-end carriers, e-boxes, HVACs or air intake manifolds, our materials deliver performance and sustainability.

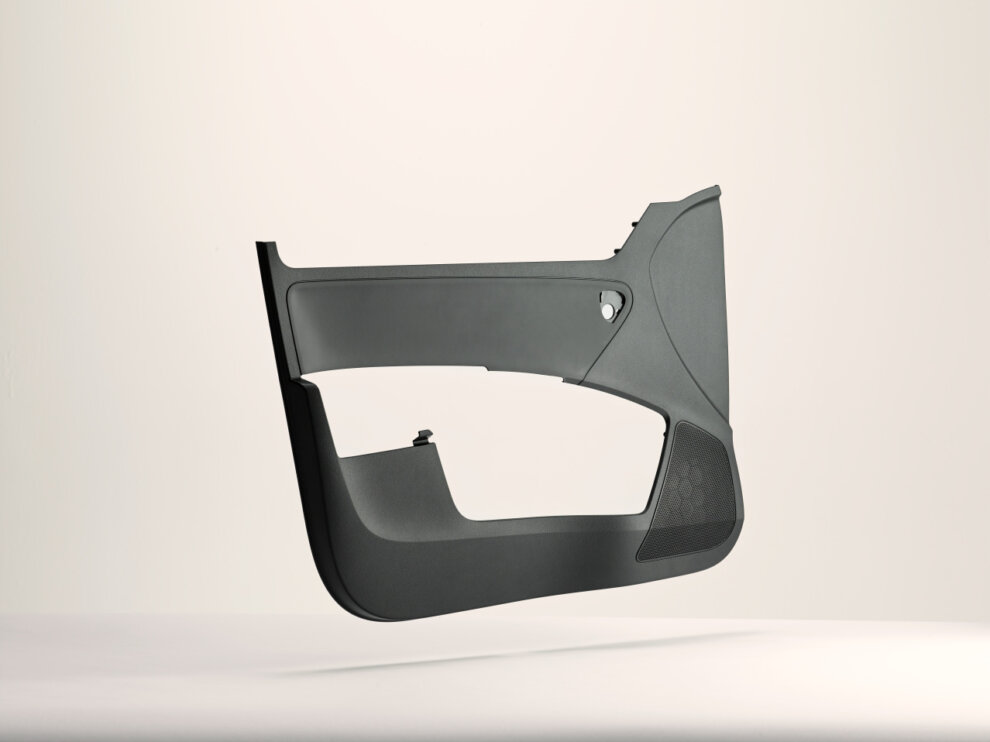

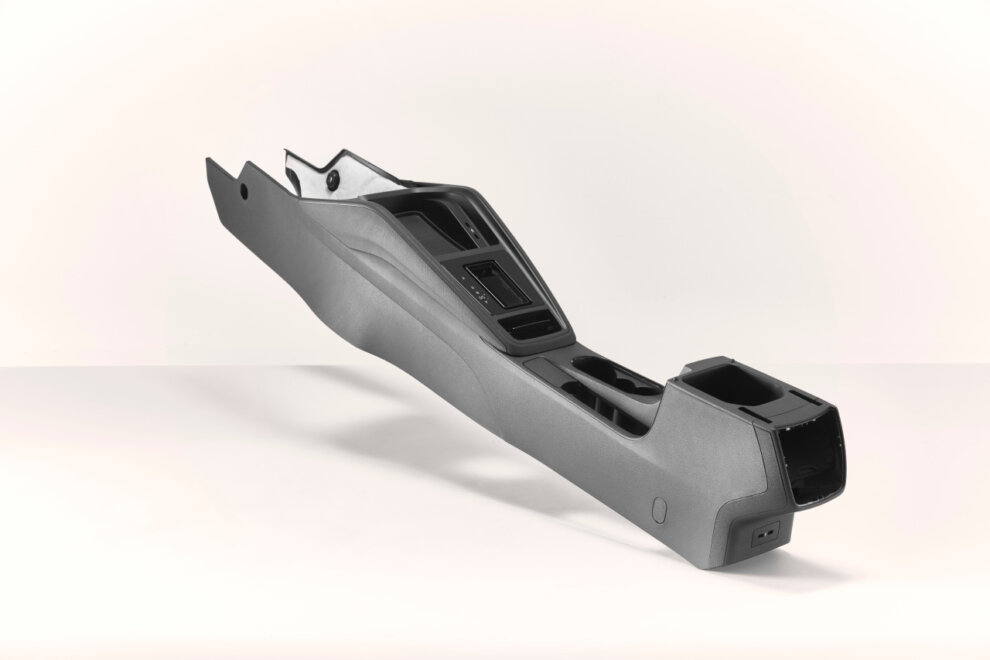

Interior

Drawing on decades of experience, we create advanced, sustainable polypropylene (PP) and thermoplastic polyolefin (TPO) solutions for a wide range of specialized interior applications, including dashboards, door panels, center consoles, trims, and structural components.

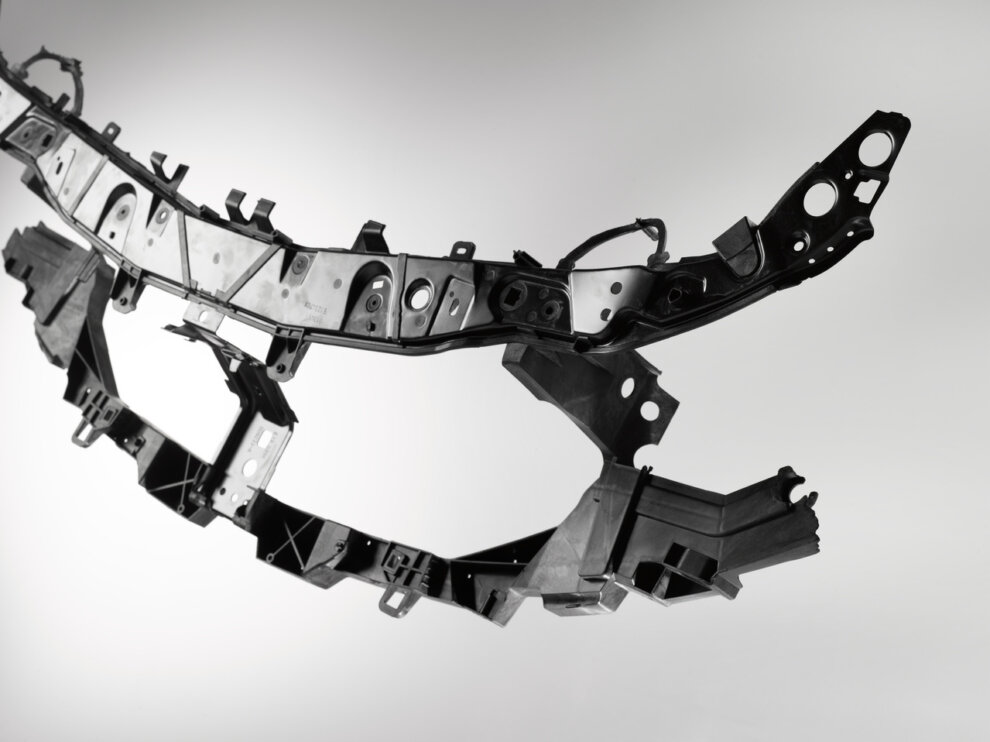

Exterior

We leverage our specialized knowledge to create cutting-edge polypropylene (PP) solutions that excel in both durability and aesthetics. Our materials are tailored for a diverse array of exterior applications, from bumpers, to body panels, trims, and more, all the while upholding our commitment to sustainability.

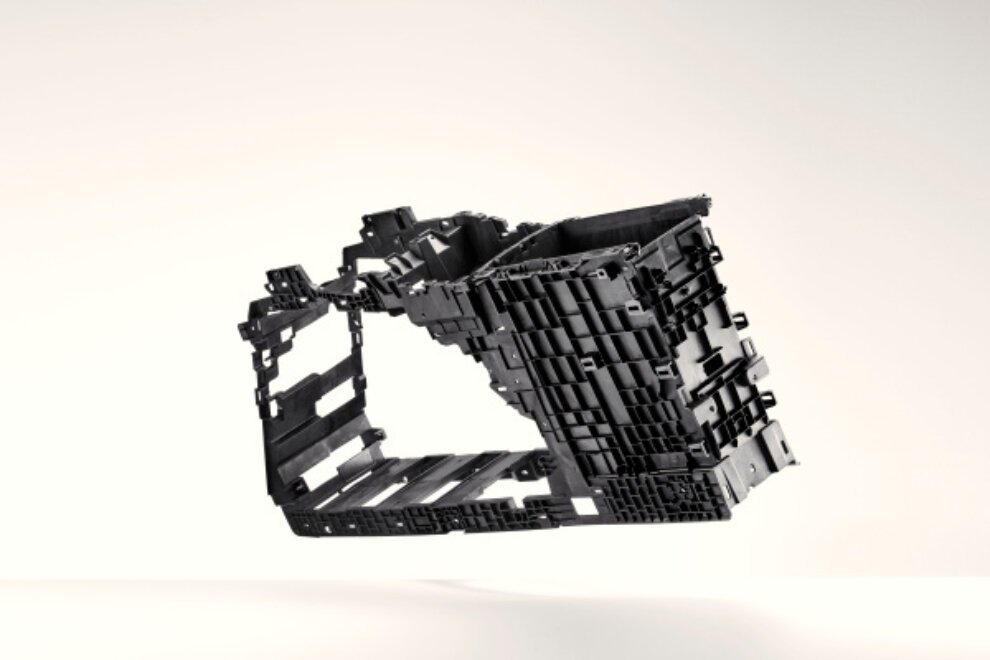

e-Powertrain and Under the Hood

Our innovative polypropylene (PP) solutions are tailored for a broad range of e-powertrain and under-the-hood applications. Whether it's battery applications, front-end carriers, e-boxes, HVACs or air intake manifolds, our materials deliver performance and sustainability.